Design & Development

Let’s build your vision

Medical device design & development

From manufacturing new to enhancing next-generation products, Harmac will support you at all stages of the product life cycle. We are happy to support you in any technical challenge you might encounter.

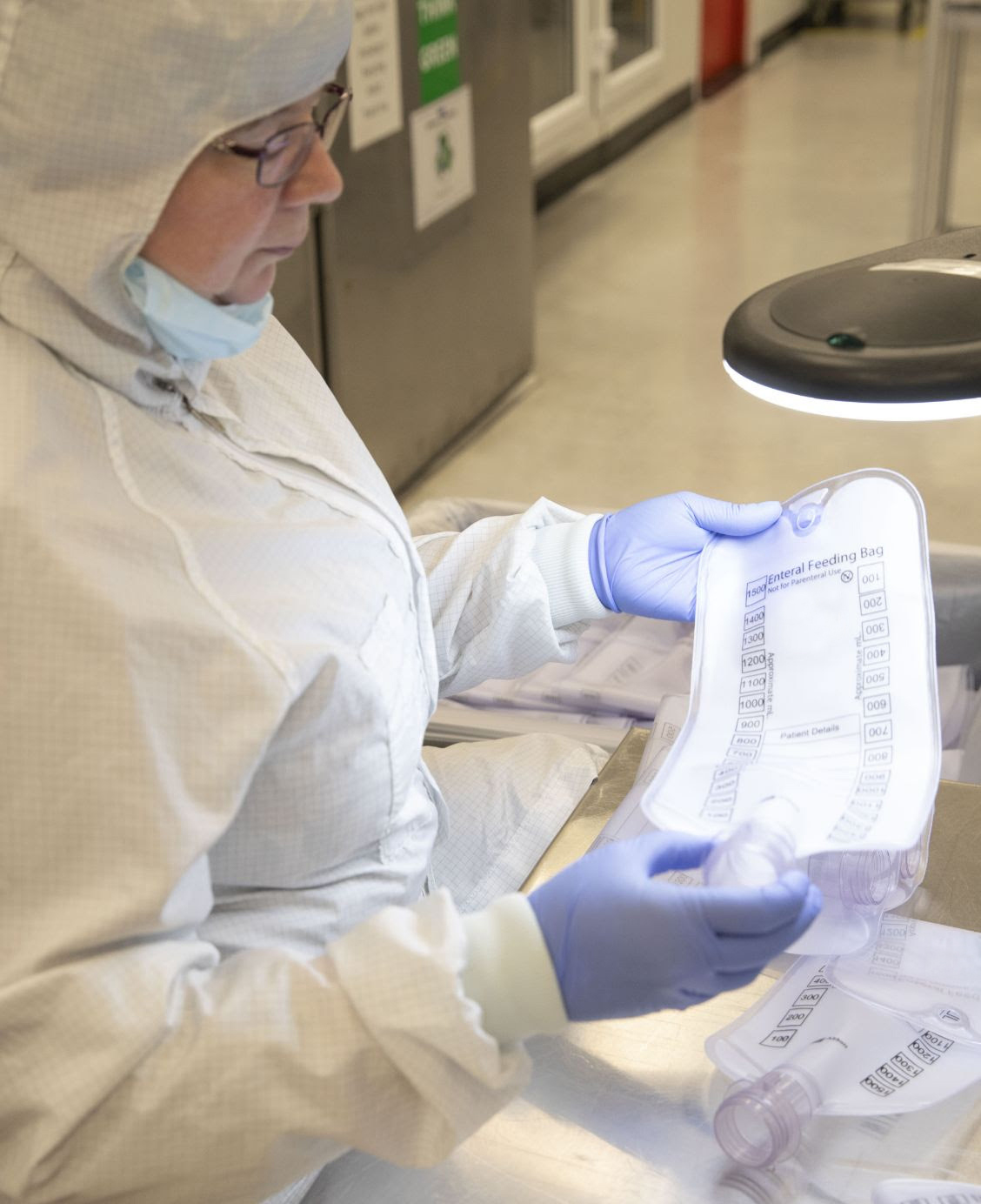

From product feasibility and initial tooling design, through volume manufacturing and assembly, to final packaging and sterilization, we work with you to ensure that the quality and consistency of your finished device will meet the needs of patients. Even if you only have a concept in mind, Harmac is here to offer our expertise, keeping manufacturability, reliability and quality at the core of our service.

How we can help

Dedicated Team

With 45 years of experience producing single-use medical devices, we apply our extensive knowledge in the design of components, sub-assemblies and finished devices to solve your product development challenges.

Every project undertaken by Harmac has a dedicated team of engineers readily available to guide you through each step of the process.

Our cross-functional, customer-focused team has an exceptional track record of delivering high quality medical devices to market within aggressive timeframes.

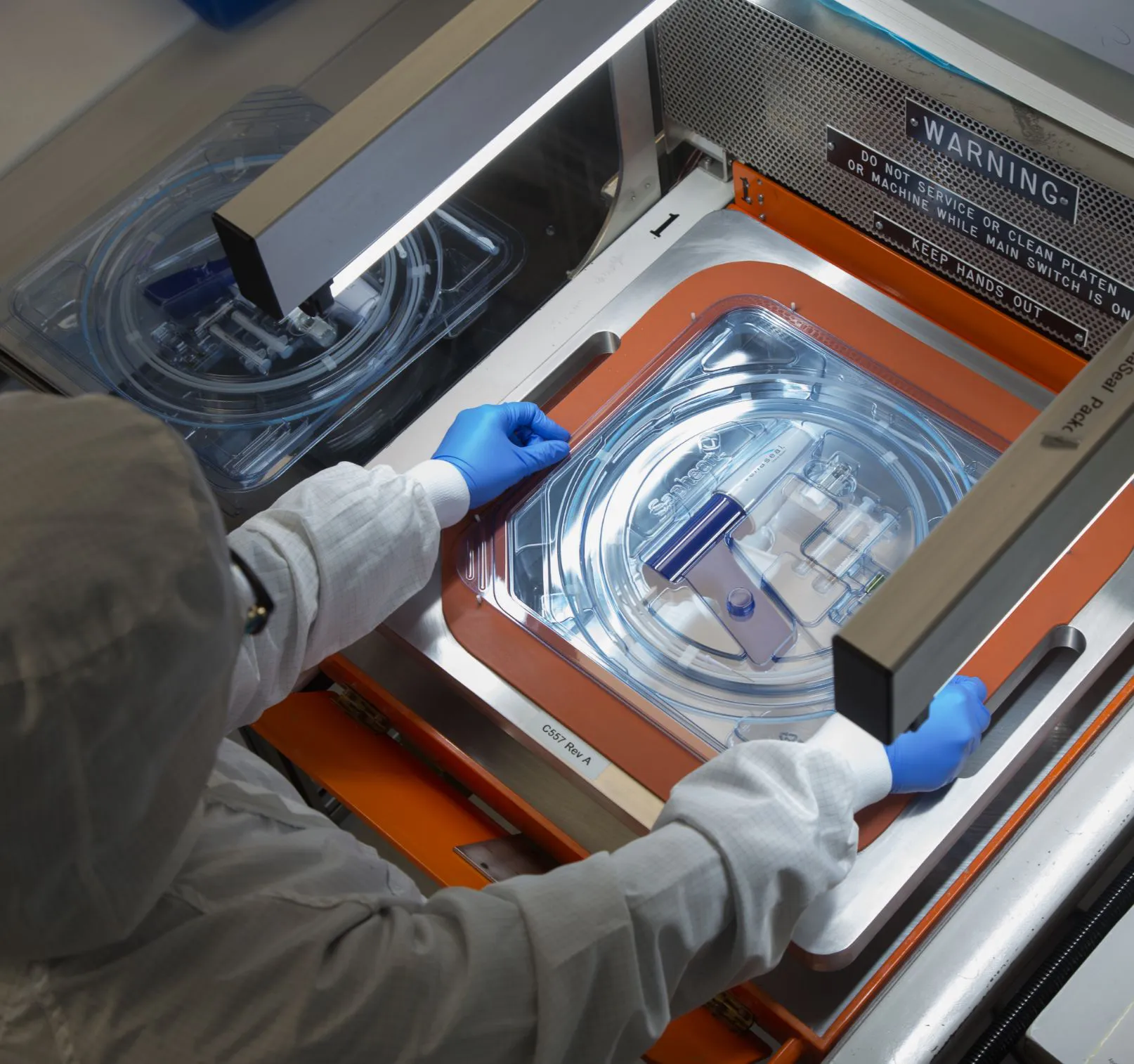

Prototype Development

At Harmac, we have in-house experts who specialize in building custom tooling and fixtures. This allows us to create high-quality prototypes quickly, helping customers test ideas, evaluate designs, and move their products forward faster.

Using advanced 3D printing and in-house machining, we can produce parts on demand, speeding up the development process and reducing the time it takes to bring a medical device to market.

Our deep understanding of medical device requirements and polymer materials means we can guide you toward the best material choices to improve device performance, durability, and patient outcomes.

Product Development Capability

Harmac provides direct access to our design and engineering teams for real-time feedback on concept performance. Using Design for Excellence (DFx) principles, we ensure each design is optimized for manufacturability, assembly, cost-effectiveness, reliability, and quality – setting the foundation for smooth scale-up and regulatory success.

Continuous Product Improvement

Driven by a Kaizen culture of continuous improvement, our teams regularly assess and refine manufacturing processes to improve efficiency, maintain quality, and meet evolving customer needs.

One of our key differentiators is our ability to transition seamlessly from manual production to automated processes without altering the product design – providing flexibility to scale while controlling costs as demand grows.

Let’s work together

No matter where you are in your manufacturing process, we can help. If you need direct access to our engineering team, you are in the right place.