Our Expertise

Bringing innovative medical devices to market is made easy

As a global CDMO with decades of experience supporting OEMs for medical devices, Harmac helps streamline the product journey – navigating stringent regulatory requirements, ensuring consistent product quality, managing global supply chains, and accelerating time-to-market.

We understand the pressures you face because we’ve been a trusted partner to some of the world’s leading medical device companies for over four decades – driving innovation, improving standards, and making a meaningful impact on patient care.

Engineering Expertise

Supporting the Lifecycle of Your Product

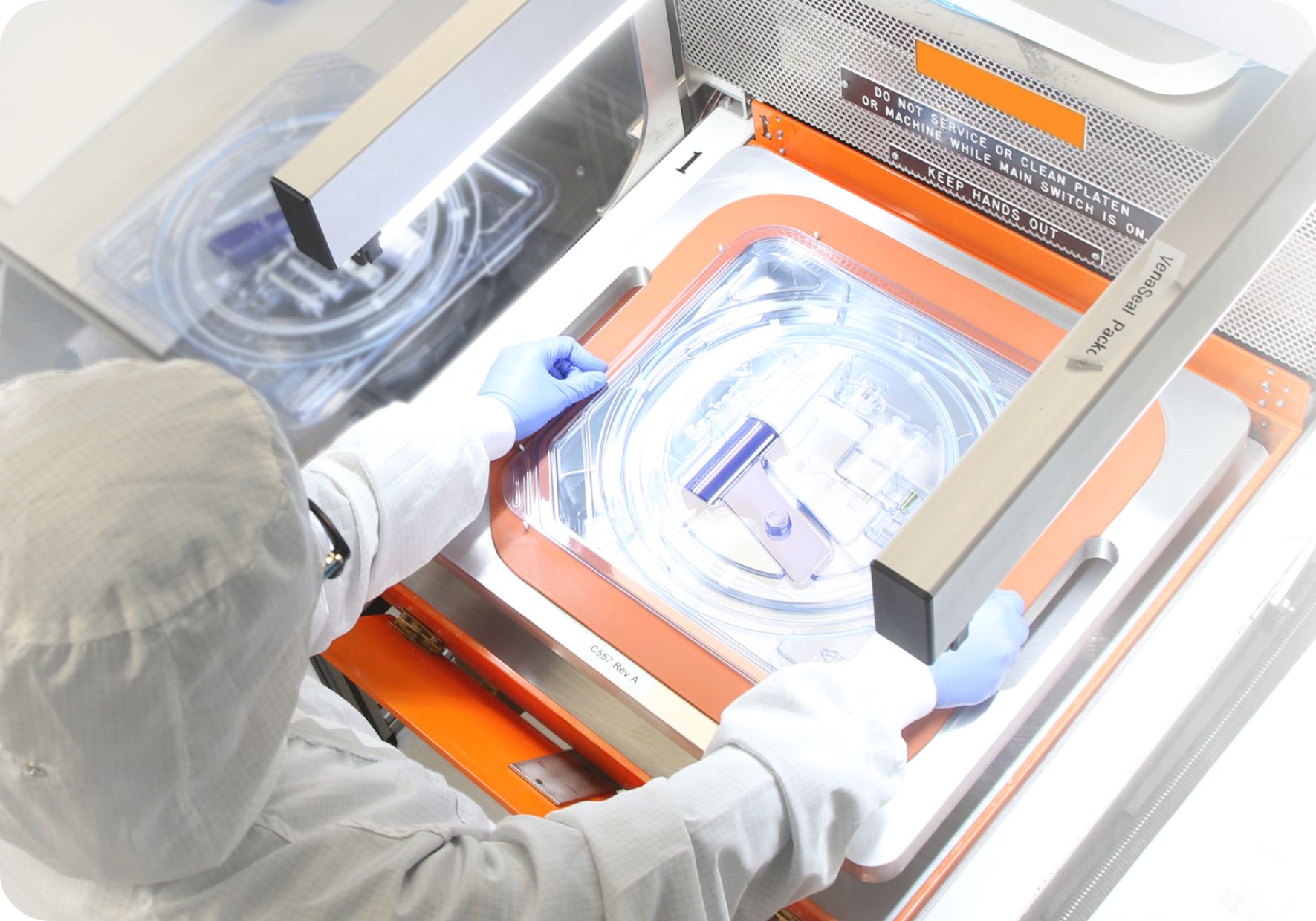

Harmac’s engineers provide a comprehensive range of value-added services that support every stage of your product’s lifecycle – all designed to help reduce costs and accelerate time to market.

From initial concept and detailed design to prototyping, full-scale production, final packaging, and sterilization, our teams deliver expertise and efficiency at every step. With over 45 years of experience, we apply our technical leadership to ensure your products consistently meet the highest standards of quality, performance, and patient safety.

How we help

Expansive Knowledge Base

Our engineers are some of the best in the industry. With a broad range of skills and technical ability,

our team has a track record of solving challenges across all stages of the product life cycle.

Customer Support

Customers receive direct access to our engineers for expert guidance in product development, mold design, tooling, assembly, automation, quality, and reliability.

Value Engineering Services

Our range of solutions include but are not limited to:

- Product Development: Early collaboration combines your product expertise with our manufacturing capabilities to enhance quality, manufacturability, and speed-to-market.

- Product Introduction: Full regulatory support, including Design History Files, Test Method Development, PFMECA, Sterilization Validations, and technical file documentation.

- Assembly Technology: Lean, cost-effective manufacturing with expertise in component selection, vertical integration, qualification, test vehicle design, and assembly processes.

- Bespoke Requests: Our team can manage your complex, custom requests, developing solutions that match your expectations.

Operational Excellence

Exceeding Expectations

Harmac’s Lean Six Sigma culture drives our leadership in medical device manufacturing, setting industry benchmarks for product quality, reliability, and efficiency.

We empower our global teams to continuously simplify processes, increase productivity, and eliminate waste.

How we help

Lean and Six Sigma

By applying Lean Manufacturing principles, we identify and remove non-value-added steps in production, streamlining workflows to boost efficiency, capacity, and responsiveness to customer needs.

Recognized Operations Leader

Our in-house tooling and custom automation systems optimize production, improve throughput, and maximize operational efficiency.

Relentless Pursuit of Excellence

We continuously eliminate waste and variation, ensuring consistent product quality and on-time delivery. All facilities operate under FDA CGMP guidelines to meet the highest regulatory standards.

Supply Chain Management

Finding Solutions That Work For You

To ensure continuity of supply and on-time deliveries, we work with the leading global suppliers of components to manage the entire supply chain process seamlessly for you.

Over our 45-year history, we have established strategic partnerships with key suppliers to ensure critical components are identified within the supply chain and managed through the Harmac supplier management program.

How we help

Harmac delivers end-to-end supply chain management that ensures reliability, quality, and efficiency at every stage. We manage supplier relationships, source raw materials, components, and packaging, and conduct risk assessments and incoming quality inspections. Our teams also handle demand planning, inventory control, warehousing, and transportation to maintain consistent product flow.

We oversee sterilization processes, assess supplier certifications for ISO, FDA, and GMP compliance, and conduct audits to ensure the highest standards in medical device manufacturing are consistently met. With tailored supply agreements and a focus on cost and process optimization, Harmac builds supply chains that are agile, scalable, and built for long-term success.

Please view the terms and conditions for our various Medical Products and associated site, below:

From product development to customer care, we uphold rigorous quality systems and continuously refine our processes to ensure exceptional performance and lasting value.

Let us accelerate your success and bring your breakthroughs to patients faster.

Let’s work together

No matter where you are in your manufacturing process, we can help. If you need direct access to our engineering team, you are in the right place.