Manufacturing & Assembly

The Heart of What We Do

The Heart of What We Do

For medical device companies, consistent quality, scalable production, and dependable delivery are critical, especially as products move from prototype to full-scale manufacturing.

At Harmac, we understand the pressure to meet patient needs while managing costs, timelines, and compliance. As a leading CDMO, we serve as a true manufacturing partner, combining expertise, advanced technology, and customer-focused flexibility to help bring your products to market with confidence.

How we help

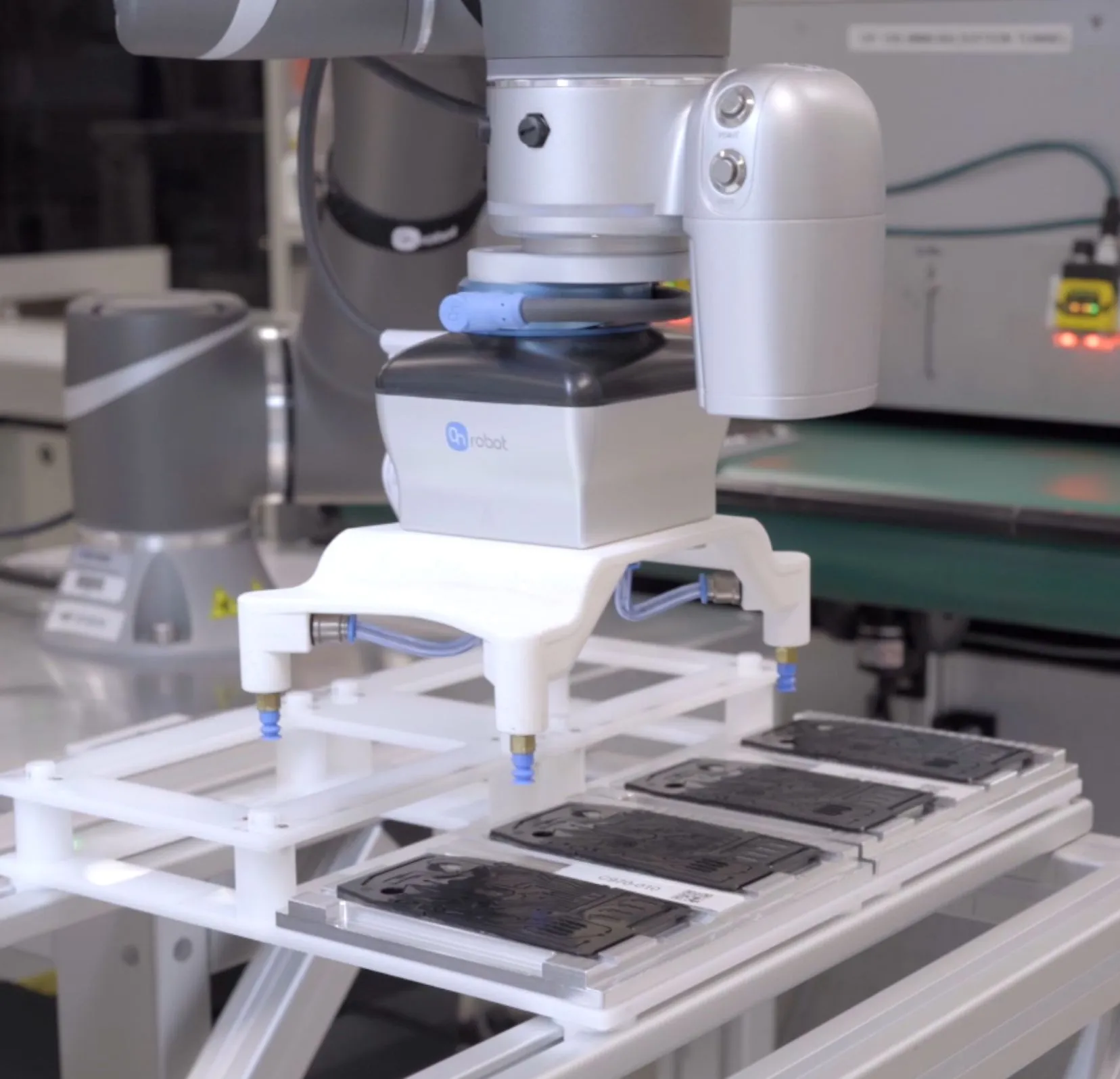

Customers count on us to deliver high-quality, single-use medical devices, every time. Backed by decades of manufacturing experience, we leverage global partnerships, automated solutions, and a vertically integrated approach to manage every phase of the product lifecycle. Our ability to scale production while maintaining strict quality and compliance standards ensures reliable outcomes, regardless of production volume.

Medical Contract Manufacturing Capabilities

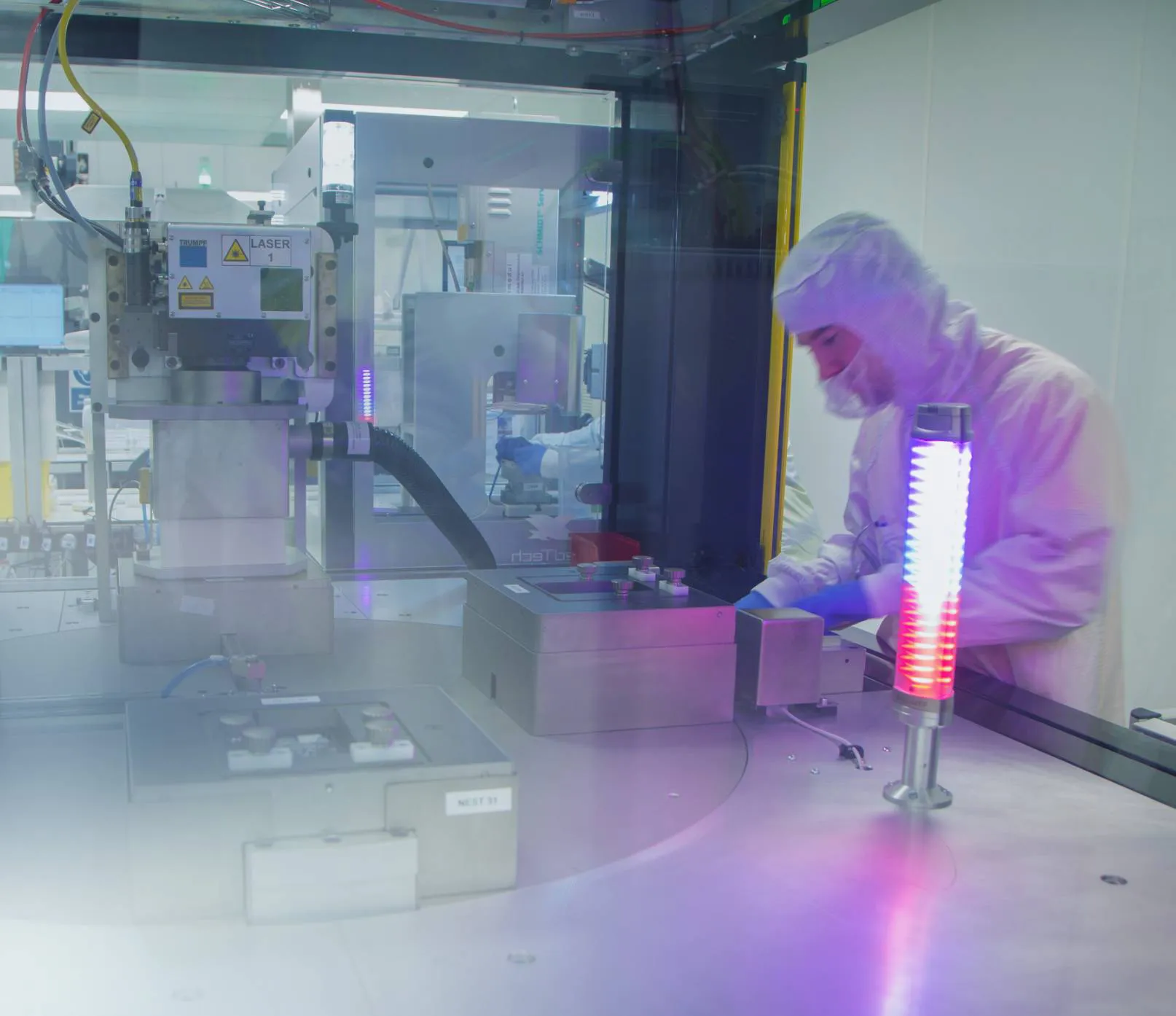

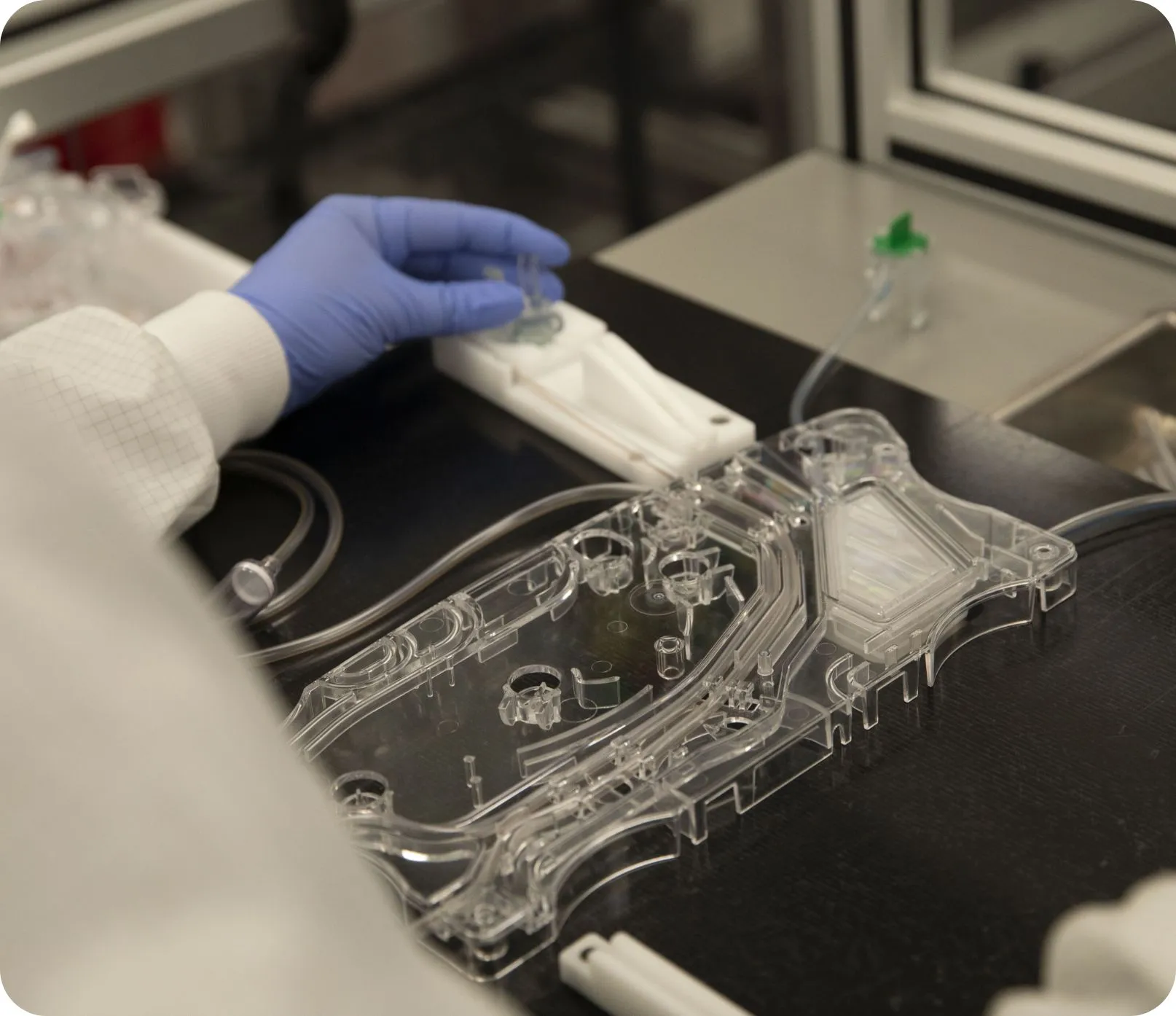

Over the past 45 years, we’ve continually expanded our advanced manufacturing capabilities. Operating in Class 8 Cleanroom and White Room environments, we offer a wide range of processes including injection molding, RF welding, ultrasonic welding, induction forming, laser cutting and marking, insert molding, two-shot molding, impulse sealing, solvent bonding, and heat sealing.

This extensive technical foundation allows us to support a broad range of product designs, materials, and medical applications.

Operational Excellence for Single-Use Medical Components

Our Lean Six Sigma culture drives our commitment to operational excellence. By eliminating waste, reducing variation, and continuously improving our processes, we deliver world-class medical devices that consistently meet or exceed customer expectations.

Every facility operates under FDA CGMP (Current Good Manufacturing Practices) guidelines, supported by disciplined methodologies such as Kanban, lean single-piece flow, TAKT time analysis, DMAIC, TPM, SMED, SPC, value-stream analysis, Kaizen, and Poka Yoke. These principles ensure precision, efficiency, and reliability at every stage of production.

Flexible Skilled Workforce

With a global team of more than 1,000 highly skilled operators, our company is equipped to handle the complexities of large-scale and high-volume medical device manufacturing and assembly, adapting to shifting market demands. Our teams take ownership of every product they build, actively participating in cost optimization, process innovation, and continuous improvement initiatives.

We stay agile in the face of change, adjusting production schedules, managing demand fluctuations, and navigating supply chain challenges to ensure uninterrupted product availability for our customers.

True Manufacturing Partnership

Whether you’re a startup launching your first device or a Fortune 500 company scaling medical production worldwide, our team is committed to transparency, trust, and long-term collaboration. Relationships are at the core of our business.

While technology continues to drive manufacturing advancements, we remain focused on building personal, lasting partnerships that reflect our values of honesty, integrity, and respect. Our proven track record in operational excellence reflects not only our expertise but also our dedication to learning, adapting, and delivering for our customers in a constantly evolving industry.

Let’s work together

No matter where you are in your manufacturing process, we can help. If you need direct access to our engineering team, you are in the right place.