Packaging & Sterilization

Ready for Market

Ready for Market

Bringing a medical device to market involves far more than manufacturing. Ensuring product integrity, sterility, and compliance throughout shipping, storage, and use is critical – and presents its own set of challenges for medical device companies.

At Harmac, our fully integrated Packaging and Sterilization services help customers navigate these complexities with confidence, delivering safe, sterile, and market-ready products every time.

How we help

We collaborate closely with customers to develop packaging solutions that protect device integrity while optimizing costs and meeting regulatory requirements. Our extensive experience includes both new packaging medical design and redesigns for existing products, with a focus on maintaining sterility, enhancing usability, and driving operational efficiency.

Through partnerships with leading thermoforming companies and sterilization providers, we offer a fully integrated, end-to-end solution that simplifies the entire packaging and sterilization process.

Medical Device Sterile Packaging Experience

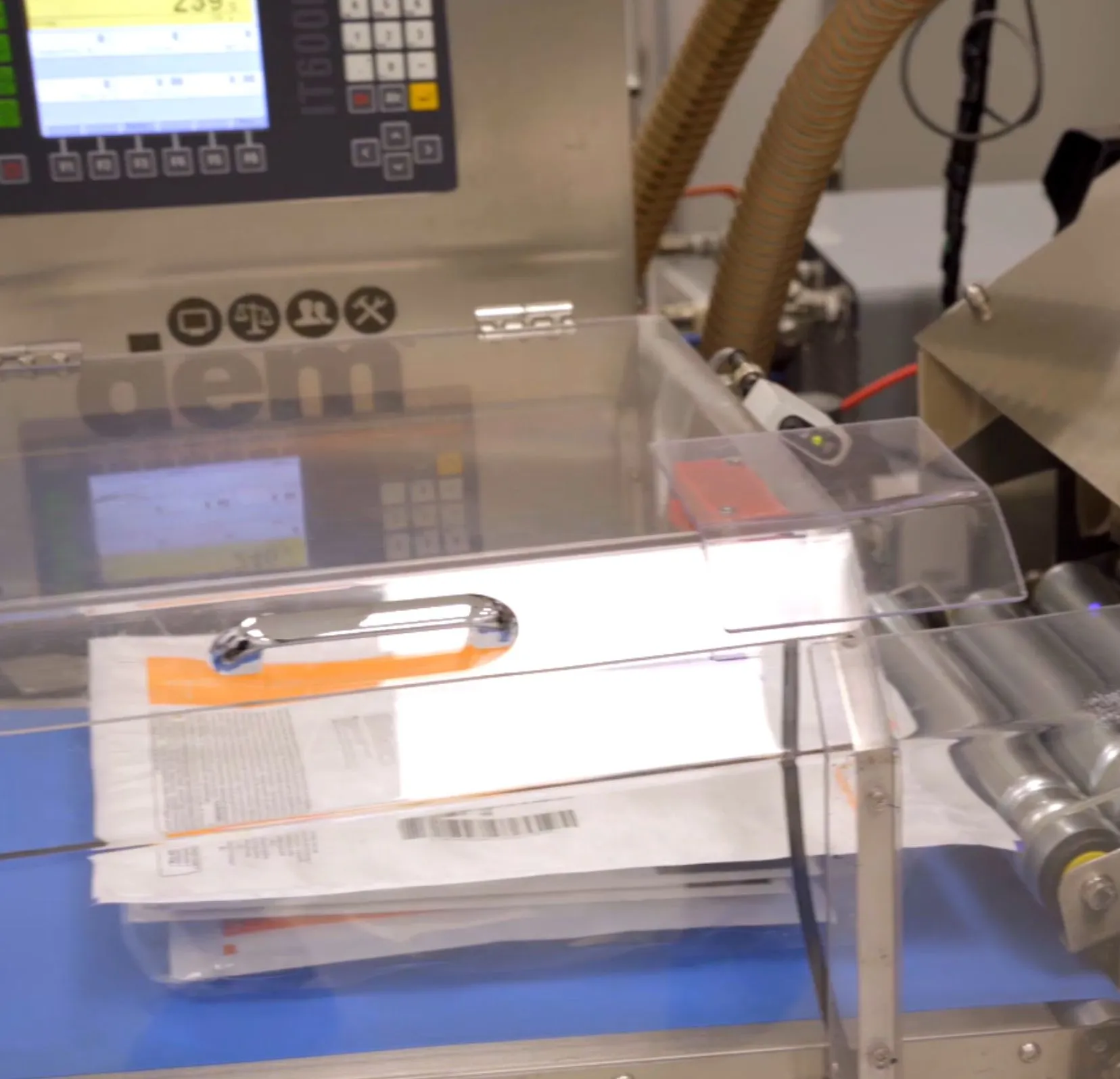

Harmac’s packaging capabilities cover a comprehensive range of options to meet the diverse needs of single-use medical devices. We offer sterile barrier packaging solutions with finished device labeling, as well as high-speed, fully automated items for pouch sealing, tray sealing, form-fill-seal, and bulk packaging – all designed to maintain product safety and consistency through every stage of handling and distribution.

Automated Medical Device Packaging, Testing and Validation

To ensure every package performs reliably, we conduct extensive testing and validation, including tensile strength, burst testing, seal integrity, transportation simulation, and aging studies. These validations ensure that devices remain sterile, secure, and effective throughout their shelf life and supply chain journey.

Medical Device Labeling Services

Our packaging services extend to comprehensive device labeling solutions. We support label design, production, barcoding, logo placement, and printing, ensuring that every product is clearly identified, accurately labeled, and fully compliant with global regulations.

Sterile Barrier Packaging Solutions

Harmac also offers a full suite of medical device sterilization packaging solutions, including Ethylene Oxide (ETO), Gamma Radiation, and Electron-Beam (E-Beam) sterilization. We work closely with customers and sterilization partners to select the most appropriate method for each device, balancing regulatory requirements, material compatibility, and cost considerations.

By partnering with us, customers simplify the complexities of packaging and sterilization while ensuring that devices reach patients safely, are sterile, and ready for use.

Let’s work together

No matter where you are in your manufacturing process, we can help. If you need direct access to our engineering team, you are in the right place.