Quality Assurance

Committed to Patients. Committed to Quality.

In the medical device industry, there is no margin for error.

Patient safety depends on precision, consistency, and uncompromising quality. At Harmac, our commitment to quality is deeply embedded in our culture and reflected in everything we do.

From product design and development to manufacturing, packaging, and customer care, every Harmac team member shares the responsibility to uphold the highest standards of quality and compliance – because behind every product we make is a patient who relies on it.

Quality goes beyond simply meeting regulatory requirements.

We view it as a core pillar of our business and a driver of continual improvement. Our robust Quality Management System (QMS) supports world-class manufacturing processes that consistently deliver reliable medical devices across the entire product lifecycle. We continually evaluate and enhance our systems to ensure ongoing compliance, process efficiency, and customer satisfaction.

Quality Policy

At the heart of our approach is a simple promise: The Harmac team is dedicated to providing our customers with world-class medical products and services.

This commitment drives every decision we make, ensuring that our products consistently meet – and often exceed – the expectations of patients and customers

Certified for Operational Excellence

Harmac operates a fully digital, company-wide Quality Management System that is compliant with all applicable regulations and industry standards, ensuring traceability, accuracy, and full control of all quality processes.

Our system is regularly praised by auditors as one of the strongest and most comprehensive in the industry. It supports the production of Class I, II, and III medical devices – including those requiring Premarket Approval (PMA) – in full compliance with all applicable regulations and industry standards.

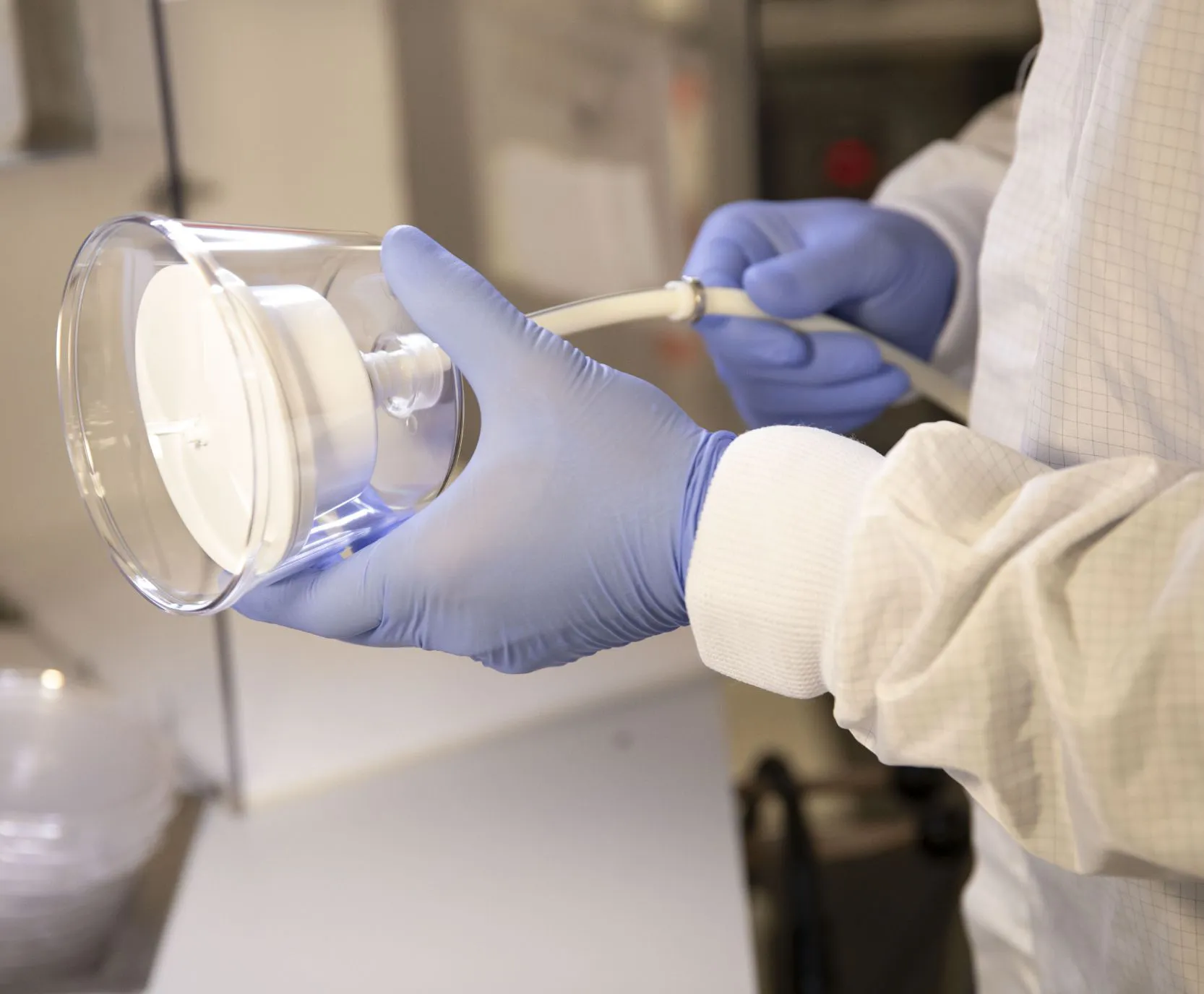

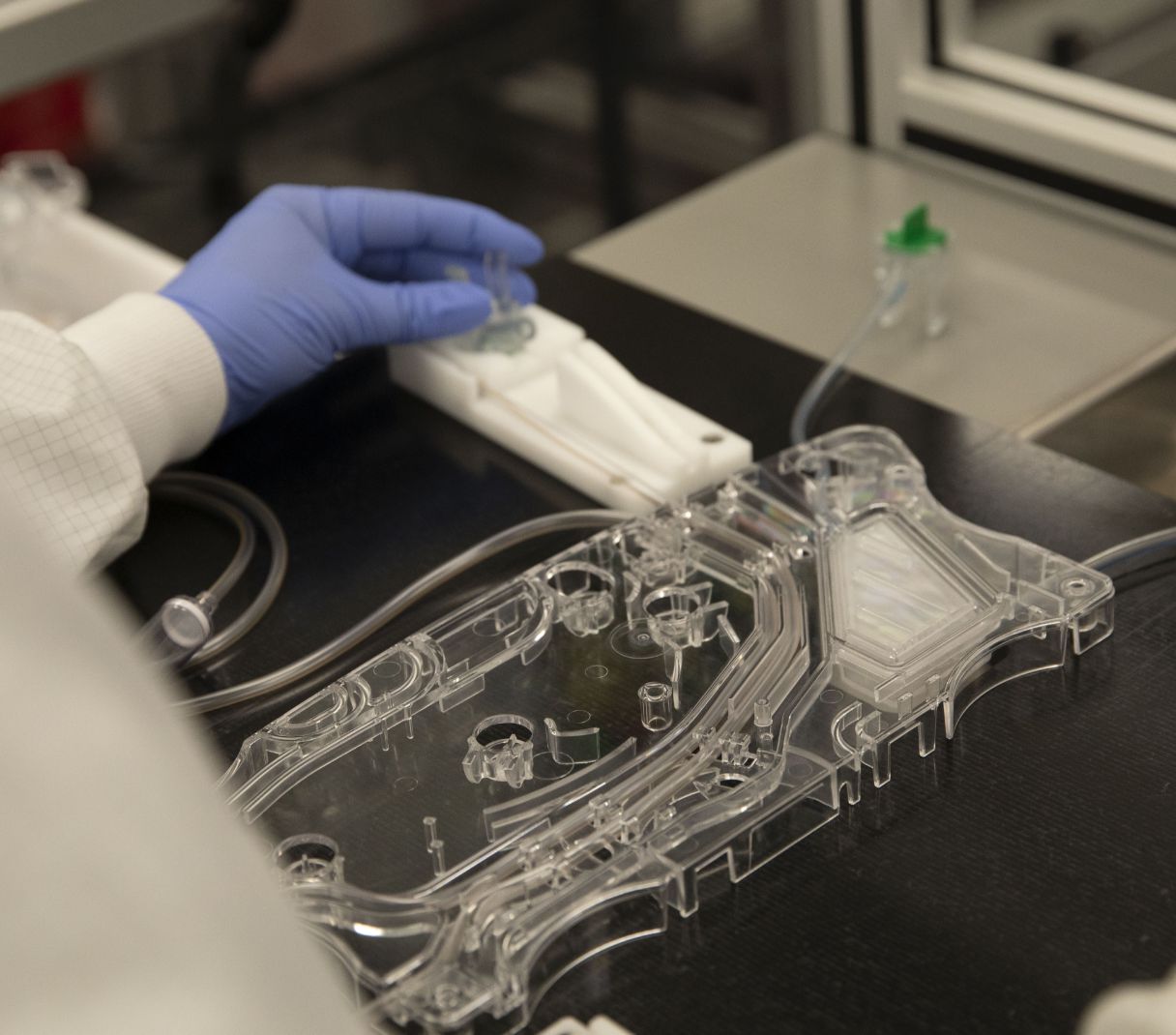

All Harmac facilities operate certified ISO 14644-1 Class 8 cleanrooms, with the flexibility to achieve Class 7 certification where required. These controlled environments support the safe production of high-quality single-use medical devices for a wide range of therapeutic applications.

Regulatory & Compliance Standards

We take pride in our global regulatory compliance, ensuring peace of mind for our customers. Harmac maintains certifications to:

Our designers, technicians, and toolmakers collaborate directly with customers to align automation solutions with production goals, optimizing speed, repeatability, flexibility, and overall efficiency, while ensuring compliance with global regulatory standards. By standardizing tooling across multiple locations, we minimize variation, reduce supply chain risks, and lower total cost of ownership for our customers.

A Foundation for Long-Term Business Performance

Quality assurance at Harmac is not a one-time achievement – it is a continuous journey. Our teams actively collaborate to monitor performance, implement real-time improvements, and uphold a strong culture of accountability across all business functions.

This ongoing focus not only ensures product quality but also strengthens our operational performance, enhances customer satisfaction, and supports long-term success for our partners.

At Harmac, quality isn’t simply a department – it’s a company-wide responsibility built into every process, every product, and every partnership.

Let’s work together

No matter where you are in your manufacturing process, we can help. If you need direct access to our engineering team, you are in the right place.