Tooling & Automation

Medical Device Tooling. Getting the Right Pieces In Place.

As medical device companies scale production, they often face complex challenges.

These include maintaining consistent product quality, managing labor and supply chain costs, and meeting strict regulatory requirements – whether producing in low or high volumes.

How we can help

Our tooling and automation capabilities are designed to scale with your product’s success.

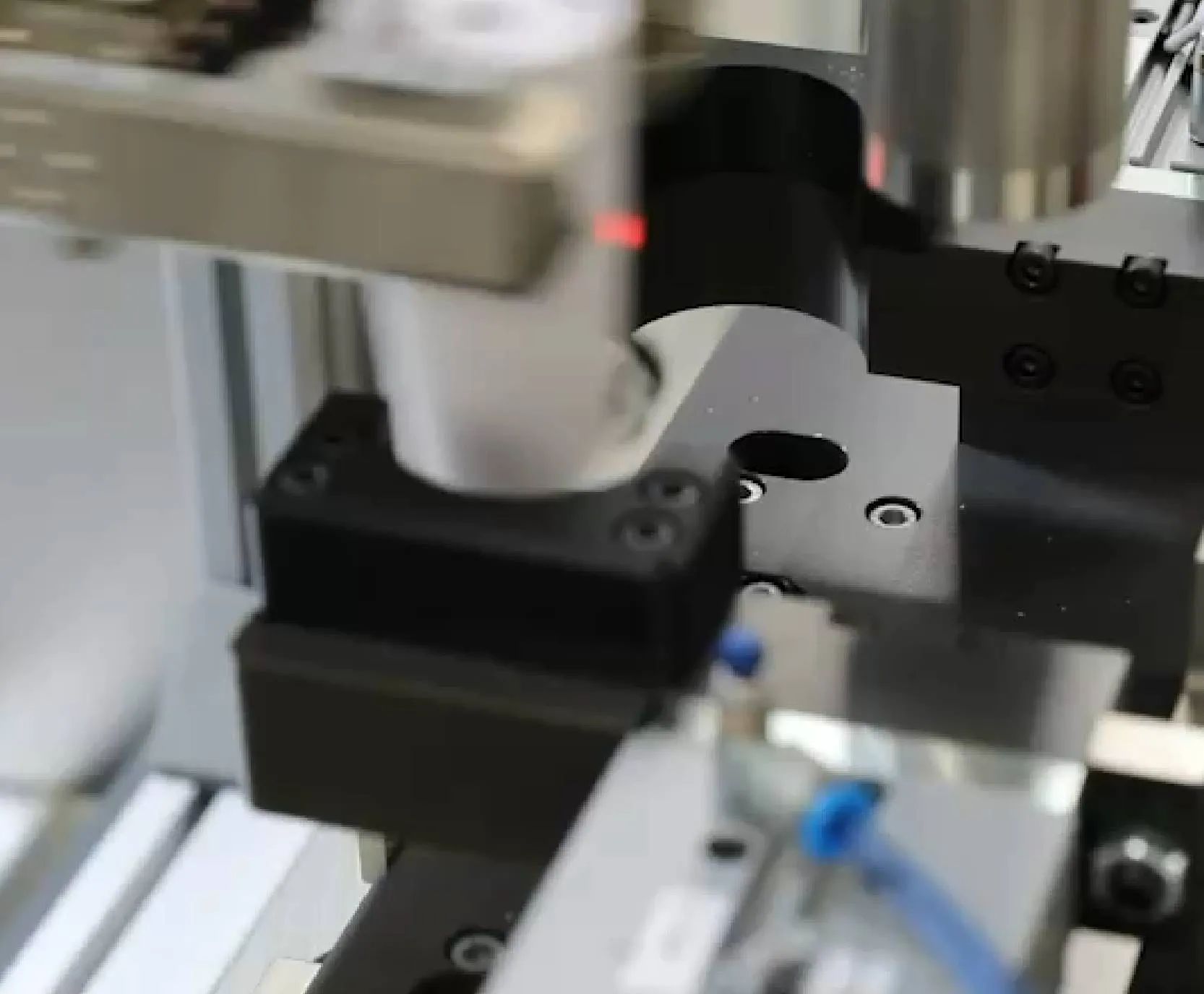

In-house skilled technicians, automation engineers, and product development teams work together to design, build, and refine flexible, proprietary semi-automated and fully automated systems that meet evolving production demands, while maintaining the highest levels of quality, consistency, and regulatory compliance.

Tooling Design Experts

Across our global facilities, Harmac operates in-house production and fabrication centers where we develop custom medical tooling and proprietary automation. This integrated approach translates directly into key advantages for our partners in quality, speed, and cost-efficiency.

Our designers, technicians, and toolmakers collaborate directly with customers to align automation solutions with production goals, optimizing speed, repeatability, flexibility, and overall efficiency, while ensuring compliance with global regulatory standards. By standardizing tooling across multiple locations, we minimize variation, reduce supply chain risks, and lower total cost of ownership for our customers.

Integrated Services

No two projects are the same, which is why we tailor tooling and automation strategies based on device complexity, production volume, material requirements, and application. Our approach focuses on minimizing variables that could impact product quality or slow time-to-market.

We leverage a range of solutions, from simple ergonomic fixtures that optimize manual steps, to advanced robotic automation and vision systems that ensure precise, consistent manufacturing across every batch and every patient. In-house automation applications span component handling, manufacturing processes, and final packaging, giving customers confidence in every unit produced.

Injection Molding Design

Harmac partners with leading injection mold manufacturers and toolmakers to fine-tune designs for optimal performance and manufacturability. By getting involved early in the design process, we help transform initial concepts into smarter, faster, and more cost-effective production.

Optimize material and component usage

Reduce costs

Accelerate development timelines

Our strong supplier relationships allow for close oversight during mold design and fabrication, ensuring that specifications are met, supply chains remain efficient, and costly design changes are avoided.

Medical Device Assembly Automation

Even small design decisions can significantly impact the complexity and reliability of automated production lines. Drawing on decades of manufacturing experience, we help customers optimize designs upfront to simplify automation, enhance work cell efficiency, and improve long-term scalability.

Our cleanroom production facilities utilize lean manufacturing principles and modular automated transport systems to maximize flexibility while minimizing factory footprints. For high-value, life-sustaining medical devices, our automation solutions eliminate the risk of error – embedding consistent quality directly into every product.

Let’s work together

No matter where you are in your manufacturing process, we can help. If you need direct access to our engineering team, you are in the right place.